In the world of eBikes, the battery and the motor together form the foundation of the product. The choice of motor type, particularly the difference between inner rotor and outer rotor, often determines the overall performance characteristics and riding experience. As a leading supplier of eBike drive systems, Bafang, with over 20 years of technical expertise, will now guide you through this technical discussion about the "heart of the eBike".

Basic Principles: Structural Differences Between Inner & Outer Rotor Motors

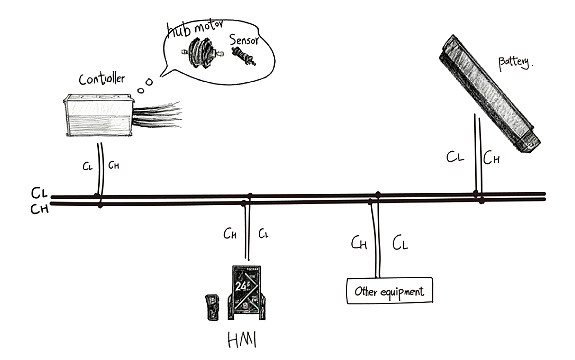

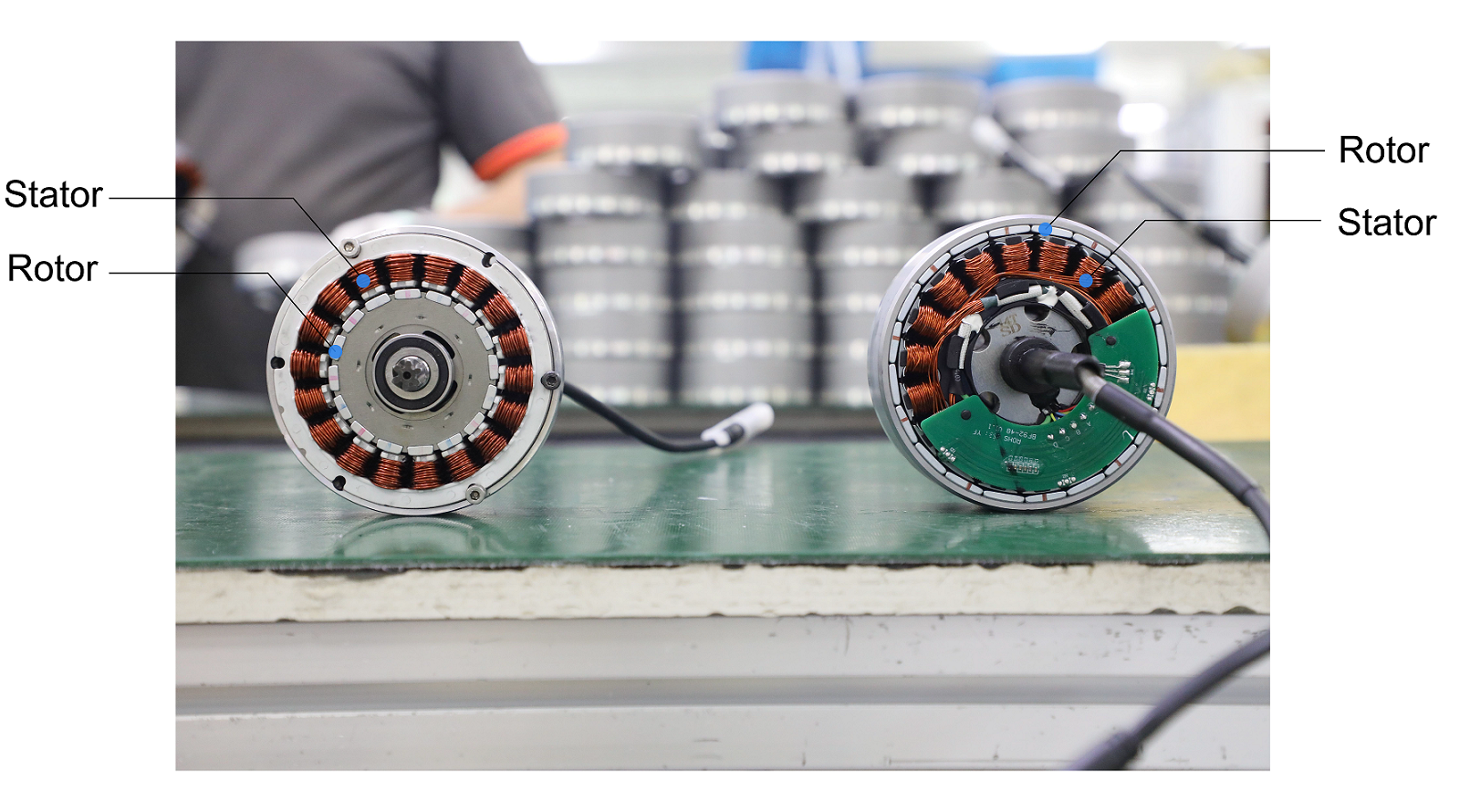

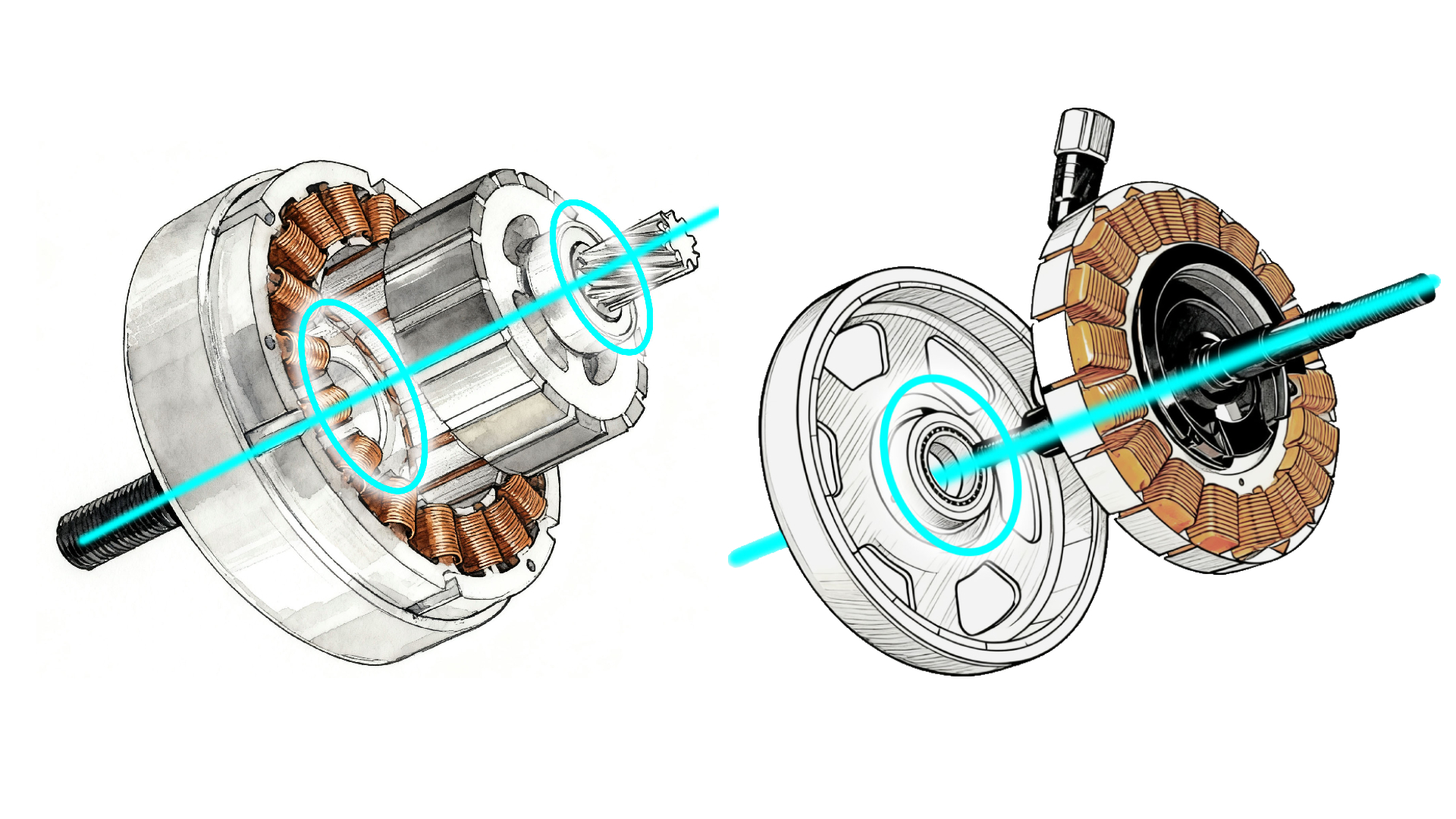

Structurally, in an Inner Rotor Motor, the rotor is located inside and rotates, while the stator is fixed on the outside. Conversely, in an Outer Rotor Motor, the rotor rotates on the outer circumference, encasing the stator at the center.

Diagrams below:

Inner Rotor Structure, Outer Rotor Structure

Inner Rotor Structure, Outer Rotor Structure

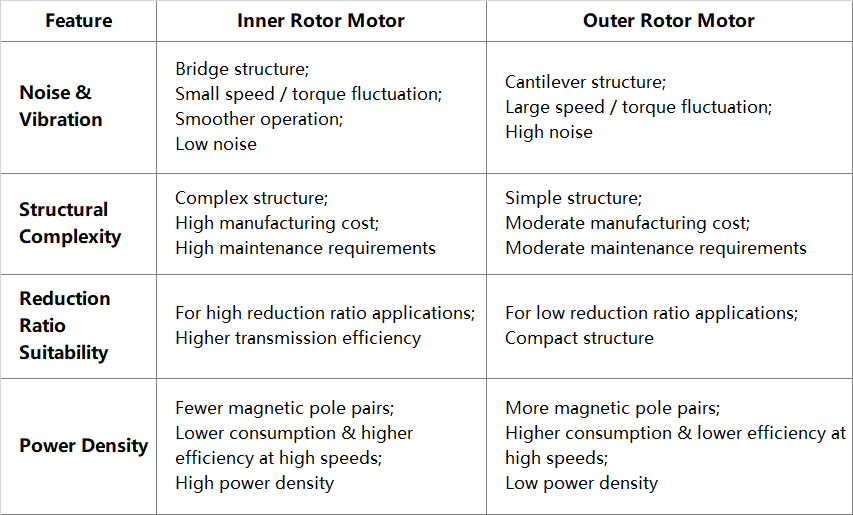

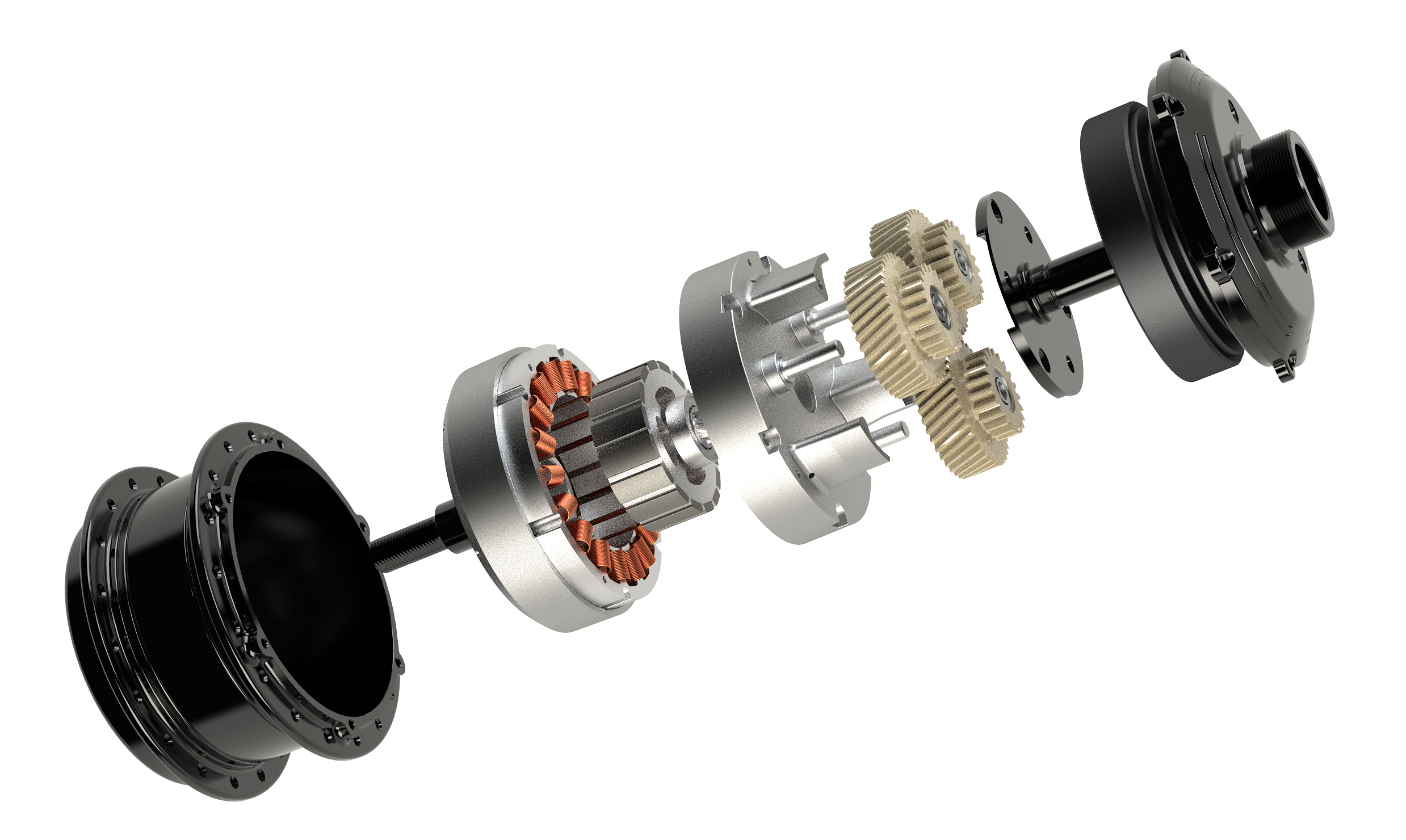

In the eBike sector, most motors feature a "stator + rotor + gear reduction mechanism" design, which is also where Bafang's technical strengths are concentrated. For ease of understanding, the following comparison is based on motors with gear reduction mechanisms and similar sizes:

Structure diagrams:

Bridge Structure, Cantilever Structure

Bafang Hub Motor Structure Examples:

Inner Rotor Gear Reduction Structure

Outer Rotor Gear Reduction Structure

Bafang Product Examples:

- Inner Rotor Motors, suitable for eBike models requiring excellent noise control and high transmission efficiency:

- H700 (250W Auto 2-Speed Hub Motor) – Urban Commuter eBikes

- H650 (3000W Hub Motor) – Off-road & Leisure eBikes

- M210 (250W Mid-drive Motor) – City and Tour eBikes

- M620 (1000W Mid-drive Motor) – Mountain eBikes

- Outer Rotor Motors, better suited for models prioritizing cost-effectiveness and structural simplicity:

- H300 (250W Hub Motor) – City and Tour eBikes

- H550 (750W Hub Motor) – Fat-tire eBikes

Please note that the motor is just one part of the eBike system. The seamless integration of the controller, battery, display, and overall bike design is equally crucial. We are committed to providing complete interconnected drive solutions, ensuring every eBike equipped with a Bafang system delivers outstanding performance and reliable quality.

Conclusion: Technology Serves the Experience

There is no absolute superiority between inner rotor and outer rotor motors; the best choice is simply the one that fits the user’s needs. Bafang consistently adheres to a "user-centric" R&D philosophy, continuously advancing the innovation and integration of motor technology. We believe the future of eBikes will be smarter, more efficient, and better serve the personalized needs of every cyclist.

We hope this article helps you gain a deeper understanding of motor technology and choose the right model.

On your riding journey, Bafang is with you all the way!