As a professional provider of eBike drive systems, Bafang consistently pushes boundaries to meet higher market standards. With Bafang products fully upgrading to CAN communication, many users are curious: What's the difference between CAN communication and the previous UART communication? What does this upgrade mean?

This article provides an easy-to-understand explanation.I. What is a Communication Protocol?

A communication protocol can be simply understood as the "rules of conversation" between devices. Just like human communication requires a common language and grammar, electronic components in an eBike need a set of standard rules to ensure smooth and accurate data transmission.

Different application scenarios in the industrial field use different types of communication protocols, such as UART, USB, Wi-Fi, Bluetooth, 4G/5G, HTTP, CAN, LIN, etc. This article focuses on UART (Universal Asynchronous Receiver / Transmitter) and CAN (Controller Area Network), commonly used in eBike drive systems.

II. Which Components in an eBike Drive System Need to "Talk"?

The electronic components of a smart eBike form a micro-network, requiring continuous information exchange, such as:

- Battery Management System (BMS): Monitors battery status and protects battery safety.

- Motor Controller (ECU): The core control unit that determines power output.

- Display (HMI): The human-machine interface displaying vehicle status.

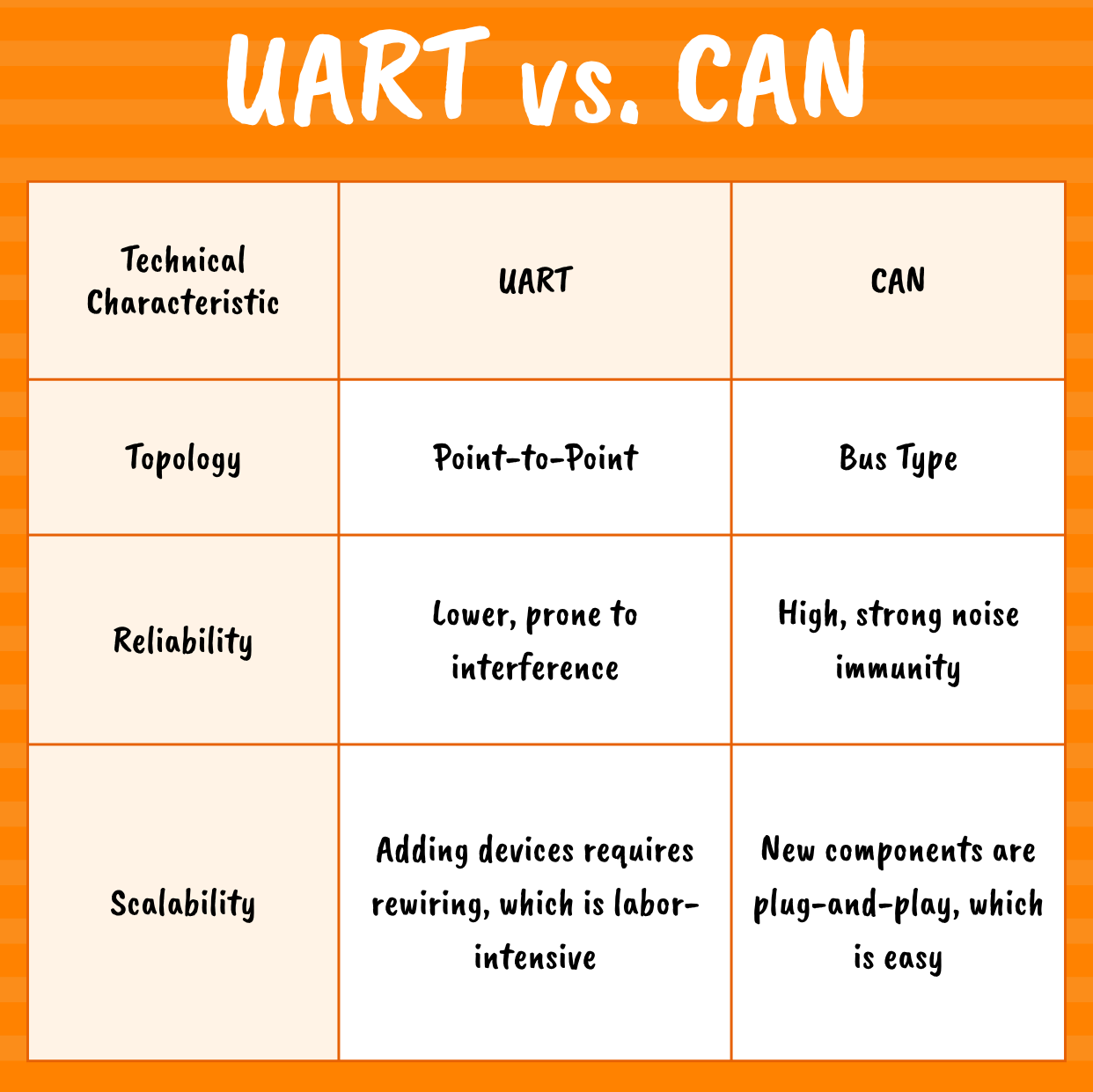

III. Core Differences & Practical Impacts: CAN vs. UART

Although both handle communication, there are significant differences in technical aspects and real-world experience:

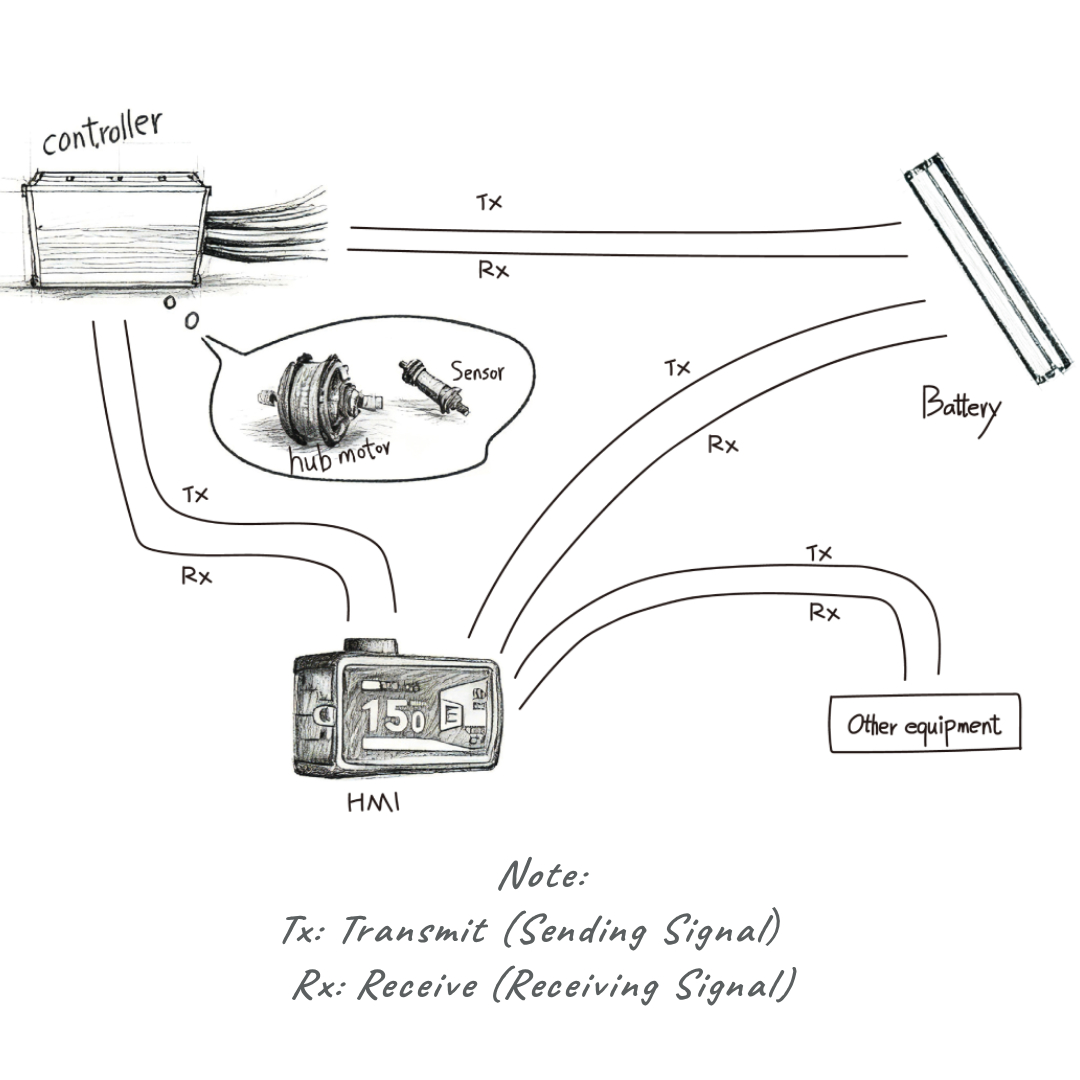

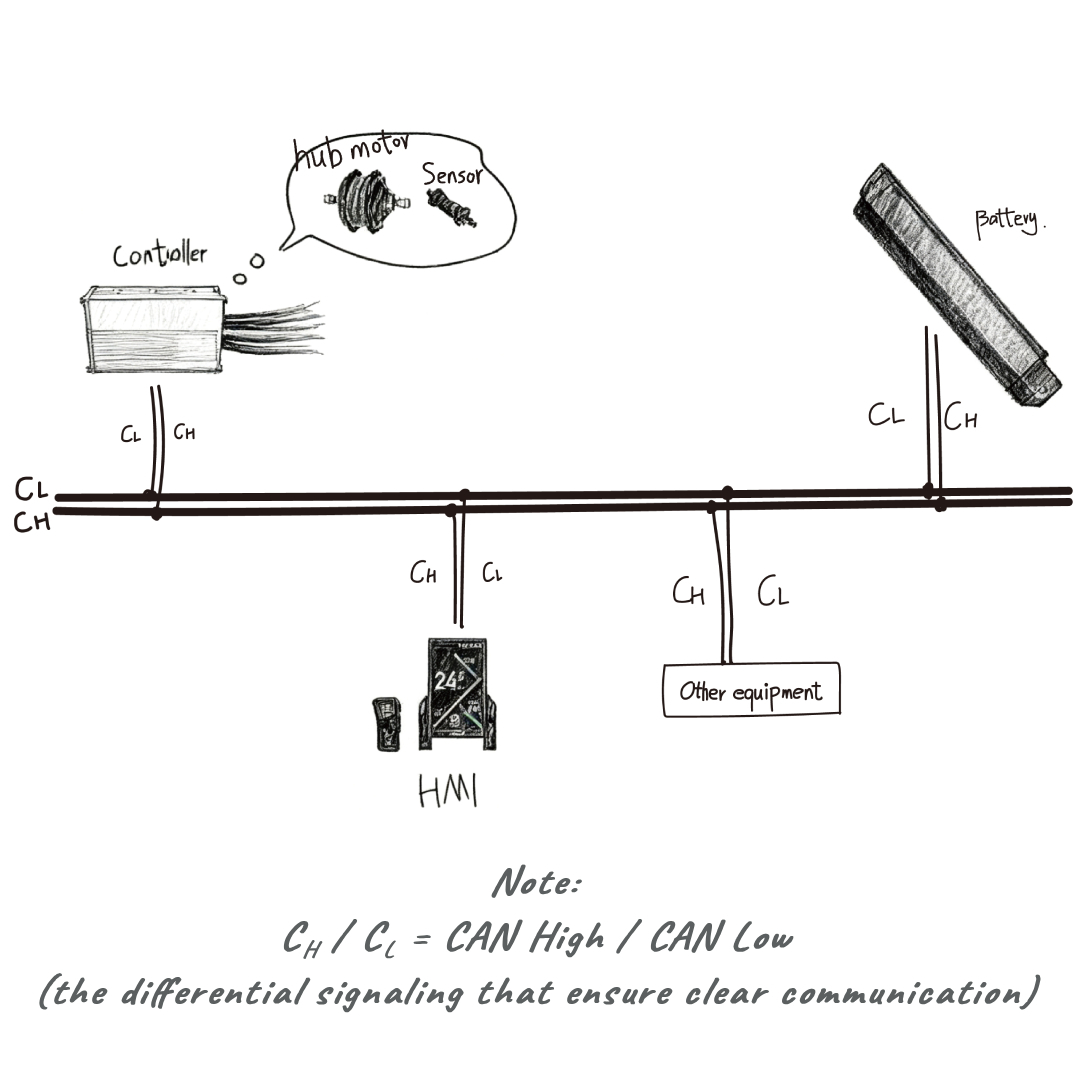

1) Topology: One-on-One vs. Group Chat

- UART is like a private conversation between two people. One speaks, the other listens. This method is simple and direct, suitable for specific, simple tasks.

- CAN is like an efficient team meeting. Any member can speak at any time, all members can hear, and only respond to information relevant to them. Everyone follows established rules of procedure to ensure orderly, efficient communication and consistent information. Even with external interference, it can automatically re-transmit, ensuring commands are received correctly.

UART Topology Diagram (using a hub system as an example):

CAN Topology Diagram (using a hub system as an example):

2) Reliability: Normal Conversation vs. Secure Call

- UART is like two people shouting in a noisy downtown area, prone to mishearing or missing information. Its single-ended signals are susceptible to electromagnetic interference, especially during high-current motor operation, leading to data errors. Furthermore, there is no verification or recovery mechanism after an error occurs.

- CAN is like two people talking in a noisy environment with noise-cancelling headphones, capable of automatically verifying information: "Did you receive the 'brake command' I just sent? If not, I'll repeat it." Its differential signaling and error detection mechanisms ensure information is transmitted accurately without interference.

3) Scalability: Fixed Wiring vs. Plug-and-Play

- Adding a new component with UART requires not only software changes but also modifications to the hardware and wiring harness layout of related components, involving significant work and cost.

- Adding a new component with CAN simply requires connecting to the bus and adhering to the communication protocol, involving primarily software changes. It's simple and convenient, and more importantly, lays the foundation for Over-The-Air (OTA) updates for the entire vehicle and building a rich smart ecosystem.

4) Intelligence Level: Basic Reporting vs. Deep Collaboration

- In a UART system, the battery might simply report: "I have 50% capacity remaining."

- In a CAN system, the battery elaborates: "I am a battery with 95% State of Health, current temperature 38℃, remaining capacity 75%. Recommend not exceeding 18A discharge current." This allows the motor controller to intelligently adjust its output.

IV. Popular Application Areas for CAN & UART

CAN Bus is standard in automotive electronics (your car likely contains dozens of CAN nodes), and industrial automation, capable of handling various harsh environments and offering good scalability. UART, leveraging its simplicity and low cost, is widely used in benign environments like smart home devices, wearables, and common electronic products. This highlights the professional standing of the CAN protocol in complex, high-reliability systems.

V. Why is Bafang Switching from UART to CAN Communication Technology?

The technological upgrade stems from Bafang's relentless pursuit of ultimate product performance and future intelligence.

1) Safety First, Reliability Paramount: Imagine how difficult it would be if power suddenly cut out due to signal interference while riding in the rain. The CAN Bus ensures your eBike operates stably in any harsh environment – heavy rain, bumpy roads, extreme cold – giving you peace of mind on every ride.

2) Smarter, More Durable: Via the CAN Bus, more information can be exchanged. Your eBike is no longer a simple "pedal and go" machine but an intelligent partner that knows how to protect itself. The battery can request a break when it's "too tired" and deliver full power when in "good condition." This not only makes for a smoother ride but also extends battery life.

3) Unlimited Expansion Possibilities: Want an IoT smart module? Electronic gear shift? The CAN Bus makes adding these devices less efforts, truly allowing you to build your personalized smart riding ecosystem.

The shift from UART to CAN is not just an upgrade in communication technology; it's a strategic transition for Bafang from providing "power" to building an "intelligent riding ecosystem". It transforms your eBike from a simple means of transport into a safer, smarter, reliable evolving partner.

We believe true innovation comes from attention to detail and deep insight into user experience. Bafang's choice of CAN communication technology as the "nervous system" aims to provide users with a more advanced, reliable, and future-oriented way of riding.

Bafang, driving forward with you.